Shippers know that hauling containers can sometimes be more complicated than expected. Different container moving companies have various moving solutions for local and long-distance transportation. When is it best to use a full-service mover versus renting a moving truck? Is it possible that temporary storage options will be required?

Shippers and BCOs must consider these questions proactively unless they want to simply deal with the aftermath. In 2018, container and trailer damage costs were in the billions, according to Brian Straight of FreightWaves, but those costs have likely risen as demand grew since 2020. Proper container hauling can be done in five simple steps.

1. Know the Details of the Container’s Contents

While cargo shipping containers may appear uniform from afar, the size, material, and contents vary. Storage units come at 20 feet long on average, but 40 feet long containers are also common amongst oceanic shipping contracts. Shippers and BCOs must especially consider the length because the logistics of longer containers and high cubes can eliminate certain standardized shipping options.

Additionally, it’s critical to know what the cargo shipping containers hold. Are the contents living? Is it refrigerated? Cargo contents within these two categories would not qualify for transport solutions such as long-term storage. The content details are pertinent long past simply packing and loading, they are essential to ensure the end-to-end transport is stress-free.

2. Ensure You’re Properly Licensed to Use Shipping Container Equipment

Sometimes cargo shipping containers simply need a local move across the yard, street, or city. A moving quote might deter the cost-savvy shipper from wanting to pay for a short-distance full-service move.

A shipper must first decide if they need to rent a specialized forklift or crane to move the container to its final location or onto a truck bed. Then they must consider whether they have a team member with a commercial driving license (CDL). While a CDL is essential for most container hauling, there are certain situations where one might not be needed. With the container’s weight and dimensions in hand, shippers can consult state regulations and the Department of Transportation to determine if it’s within towing regulations.

3. Have a Shareable, Concise, and Well-Thought-Out Plan for Container Hauling

When hauling containers, it’s important to have a distribution plan that is clear every step of the way. Streamlined communication is imperative from the first time loading until unloading at the final destination. Long-distance moves often acquire additional team members to keep in the loop, such as a storage facility or rail hub manager.

A concise and communicable plan is not just about knowing who to communicate with, but what information to share. Staying on top of industry and partnership news will guide shippers to the right documents and data they need for every leg of the journey.

4. Outsource Shipping Container Transport to Experts

The need for a professional rise with the complexity of individual containers. Is it open side? Are the measurements outside of typical sizes? Does it require specific connections to engage refrigeration elements?

Ultimately, when it’s time to move containers, it’s time to call in the experts. Supply chain professionals are in their field for a reason – offering specialized expertise to make your daily job easier. An expert at hauling containers will offer the right insurance options and customer service to ensure that cargo shipping containers go exactly where they need to go every time.

5. Stay in Contact and Track the Status of the Container 24/7

Container transport is more than just getting commodities from one place to another. Timing is key! Constant contact and container visibility protects shippers and BCOs from losing valuable product. Miscommunicated timelines can leave a driver idling for extended times, or even cause a container drop off at an unmanned loading deck.

The right container-moving companies will go above and beyond to ensure their shippers and BCOs have access to their tracking data. With contact opportunities and real-time locations, shippers gain the right tools for the job to conquer disruptions.

Supra National Express enables full visibility of their shipments and cargo documents to speed up the traceability process and enable more dynamic and agile management. Users can:

- Search the load history

- Check load status: pending, completed or billed

- Export load history to CSV or Excel sheet

- Check the uploaded documents in the trips of each Load

- Check the load details: Arrivals/Departures, Pending Check Points, and Charges

Choose Supra National Express for All Your Shipping Container Needs

Shippers will likely see a variety of techniques when shopping container moving companies and pods offers. Hauling containers across twenty feet or twenty miles requires data, the proper licenses, logistics, the right team members, and constant visibility. Supra National Express understands this which is why they stand out among its competitors as a container-hauling solution. Get your questions answered and your freight moving by Supra today!

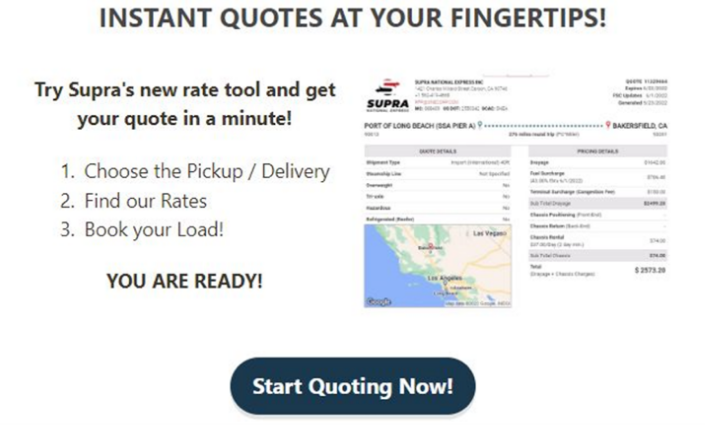

Get your quote now by trying Don’t forget to give Supra’s new Online Rate Tool a try as well!

Or get in touch with Supra’s Sales Team at (424) 267-1155 or by email: rfp@snecorp.com

Become A Partner Carrier

Become A Partner Carrier