Supply chain and logistics technology, i.e., logistics tech systems and services, continue to advance and help companies, whether freight forwarders, BCOs or other entities, have an absolute need to do more with less. Fortunately, high tech supply chain software developers are on the track and heading to help companies do more with less. The proper use of supply chain tech reduces confusion and improves operational excellence, but for many, the budgets to build technology in-house are missing. Meanwhile, third-party players, including Supra, are tackling the problem head-on by developing next-generation supply chain technologies, supply chain tech, that will support true optimization and digital transformation, such as DrayMaster and 121 Bermuda.

The answer rests in understanding the inherent challenges of transportation and logistics scalability within an aging tech stack and how innovation can streamline operations.

Limited In-House Resources to Build a High-Tech Supply Chain Industry

Supply chain companies often have limited in-house resources and budgets, making it challenging to build and maintain a next-generation technology stack. To stay competitive in an increasingly digital market, these companies are turning to third-party solutions to help them build and maintain their tech stack. For example, building the technology to reduce waste in drayage might be expensive, but Supra has created 121 Bermuda to support more street-turned containers, reducing delays and streamlining operations.

These solutions can provide access to advanced technology and expertise that may not be available in-house. This can be particularly useful for companies looking to adopt new technologies, such as artificial intelligence or the Internet of Things (IOT), but lack the resources or expertise to do so independently.

Third-party solutions can help supply chain companies save money and reduce risk. Building and maintaining a tech stack can be costly, especially for companies with limited budgets and resources. By turning to third-party solutions, companies can access advanced technology and expertise at a lower cost, as they do not have to invest in developing and maintaining these resources in-house.

Outsourcing some or all of their tech stack reduces the risk of technical failures or delays. Instead, logistics leaders can rely on the expertise and resources of the third-party provider. And in fact, more companies are turning to third-party resources to improve operational excellence. Specifically, a 2021 Gartner survey found that 74% of logistics leaders expect increased spending on outsourced logistics technology. Still, there are other issues that supply chain tech can solve that will enhance scalability throughout any economy.

Logistics Tech Unifies Disparate Data Sources

One major problem that supply chain companies often face is the issue of disparate data sources. Many companies have multiple systems and databases that store different types of information, such as customer, inventory, and container shipping data. These systems may not be connected, making it difficult to get a complete picture of the supply chain and make informed decisions.

Third-party companies can help supply chain companies connect disparate data sources from manufacturing companies through distribution centers and beyond, creating more efficient operations. These companies often offer integration and data management solutions that can bring all a company’s data into a single platform, enabling them to get a holistic view of their supply chain. This can help companies identify bottlenecks and inefficiencies and make informed decisions about optimizing their operations.

By connecting data sources, companies can also gain real-time visibility into their supply chain, which can help them respond quickly to changing customer demand and market conditions. This can enable proper supply chain optimization, as companies can make more informed and strategic decisions about allocating resources and supply chain management.

Poor Communication and Collaboration

Fulfillment centers have also suffered from challenges in communication and collaboration. Poor communication and limited collaboration can also lead to problems managing inbound deliveries and outbound pickups in the yard of a warehouse, particularly for drayage service near major ports of entry. When different parts of the supply chain do not have access to the same information, it can be challenging to coordinate the flow of goods and vehicles in the yard. This can result in missed deliveries, unexpected shortages, and other problems that disrupt the flow of goods and services.

For example, suppose a warehouse manager needs help seeing the status of inbound deliveries. In that case, they need to know when to expect a delivery and when more resources are necessary to unload and process the goods. This can lead to delays and inefficiencies in the warehouse and disruptions to the rest of the supply chain.

Similarly, suppose a warehouse manager needs visibility into the status of outbound pickups. In that case, they may not know when to expect a pickup and may need more resources to load and prepare the goods for shipping. By addressing communication and collaboration issues, companies can improve the management of inbound deliveries and outbound pickups in the yard of a warehouse. That’s also a precursory step toward leveraging cross-docking as well.

Trouble Managing Yard Access With Antiquated Supply Chain Tech

Gate and yard access are additional problems with scalability in the logistics industry. Consider the complexity and demands of the following and how technology could streamline each process for both warehouse operators and trucking companies alike:

- Coordinating the flow of vehicles. Ensuring that trucks and other vehicles can enter and exit the warehouse in a timely and efficient manner can be challenging, especially when multiple deliveries and pickups are happening simultaneously. Identifying and tracking each vehicle will go a long way to reducing the confusion of arrivals/departures and avoiding bottlenecks at the dock.

- Tracking truck appointment schedules. Keeping track of all the deliveries and pickups coming in and going out of the warehouse can be a complex and time-consuming task. Automated notifications and integrated updating systems can keep everyone informed of yard activities.

- Managing security. Ensuring the security of the warehouse is an important responsibility, including managing the gate and the flow of vehicles in and out of the warehouse. Rather than manually sorting through documents, digital systems can identify, verify and authorize entry to a gate automatically, saving tens of thousands of dollars on admin costs alone.

- Dealing with unexpected events. There are often unforeseen events that can disrupt the flow of vehicles at the gate, such as weather-related delays or equipment failures. Managing these events and finding ways to minimize their impact on the supply chain can be challenging. Again, freight technology can reorder the schedule and reroute drivers to reduce congestion.

Get on the Fast-Track to the High Tech Supply Chain With Supra

There will always be another disruption around the corner and tightening budgets. However, companies partnering up, developing, and leveraging new supply chain tech will be poised to succeed in 2023 and beyond. It’s time to face and overcome the challenges of logistics scalability by partnering with Supra and our growing suite of logistics technology services.

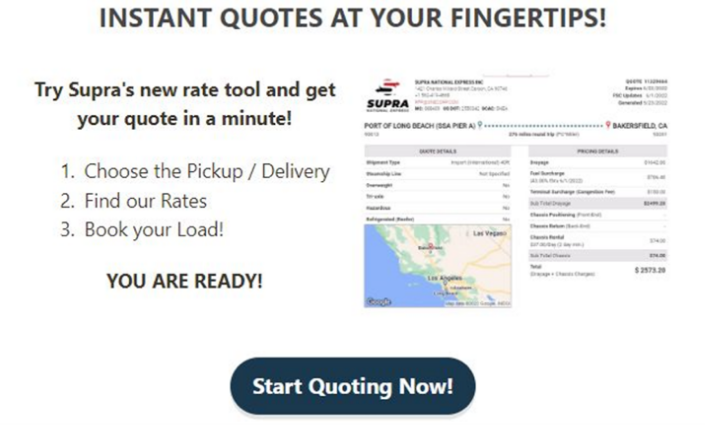

Get your quote now by trying Supra’s new Online Rate Tool and get your quote within a minute.

Or get in touch with Supra’s Sales Team at (424) 267-1155 or by email: rfp@snecorp.com

Become A Partner Carrier

Become A Partner Carrier