Data is everyone in today’s supply chain, from insight into current fuel surcharges to warehouse transfer dynamics. But is that data being put to use? According to Forbes, “ 60-73% of enterprise data sits idle on servers somewhere in the cloud, a squandered resource never tapped for the benefit of the business.” That untapped data is a massive resource and transportation optimization, but problems still exist. Why? There’s so much happening that things can and do go wrong.

Many pitfalls can prevent logistics service providers and shippers from achieving their desired outcomes. The wrong approach can lead to errors and delays, from efficient routes and adequate resources to reliable delivery methods, pushing transportation costs higher. To ensure your business runs as smoothly as possible, it’s essential to avoid these common mistakes when optimizing transportation strategies. Here are some of the most common pitfalls in optimizing transportation strategies and how Supra’s changing the narrative.

Pitfall 1: Not Understanding the Problem

Transportation optimization is among the most complex processes on the planet. It’s constantly changing and subject to enormous risks. As a result, it’s essential to understand the problem before attempting to solve it.

Part of this may include evaluating the existing transportation process, accounting for changes in lead times, and analyzing shipments for risks. When a problem is fully identified, freight management parties must look outside of the box for solutions.

Such solutions may or may not align with their typical operations and processes. However, recognizing the opportunities versus costs is the best first step. Plus, it will go a long way toward reducing confusion and prioritizing high-risk problems. Supra approaches every load with this mindset and identifies all possible issues and their solutions.

Pitfall 2: Not Utilizing Transportation Optimization Software

In today’s world, technology is essential for optimizing transportation strategies. Route optimization software can help companies plan efficient routes and reduce costs. Companies should also consider using other types of technology, such as GPS tracking systems and automated dispatching systems, to improve their transportation strategies further.

One such technology that is gaining traction in the logistics industry is NavTrac, an AI-powered digital yard management system. NavTrac leverages computer vision to capture and track assets in digital form, thereby automating the asset inventorying process and eliminating recording errors. This helps companies gain real-time visibility into their assets, enabling them to optimize their supply chain operations, reduce costs, and improve customer service.

People can still make mistakes even with a plan to use technology fully. People can still make mistakes. In other words, transportation optimization requires training staff on the correct use of technology, clear instructions that must be followed, employee performance tracking, and feedback when needed.

Pitfall 3: Failing to Consider Safety

Safety is integral to a successful transportation strategy and should be noticed when planning and executing operations. Failing to prioritize safety can lead to violations or fines from governing bodies and other problems such as catastrophic accidents and costly litigation. Still, logistics software can help companies prioritize safety by providing more data on resource availability, including labor resources and tracking equipment maintenance.

Companies must be proactive in implementing safety measures that comply with industry regulations. Additionally, Supra’s use of advanced technology, including NavTrac, helps to improve safety by carefully and accurately tracking all gate movements and ensuring everyone knows what’s happening. That additional data stream helps to reduce risk in the yard and avoids bottlenecks at the dock. In turn, everyone enjoys a safer and more successful loading/unloading process.

Pitfall 4: Not Planning for the Future and Lacking Agility

When optimizing transportation strategies, companies should consider their current needs and plan for future changes. This includes evaluating trends in the industry and anticipating changes in customer demands. Companies should also consider regulatory developments affecting their operations and factor these into their plans.

Responsiveness also enables companies to react quickly when unforeseen issues arise. This helps them avoid delays or increased costs, allowing them to remain competitive in the market. Companies should ensure that they have processes that enable quick responsiveness and adaptation to changes.

Overcome These Barriers With Supra and Freight Optimization Software

Overall, optimizing your transportation strategy requires careful planning and the ability to adapt quickly. Companies should prioritize safety measures, plan for future changes in customer demands, and be responsive when unforeseen issues arise. That starts with choosing the right partner.

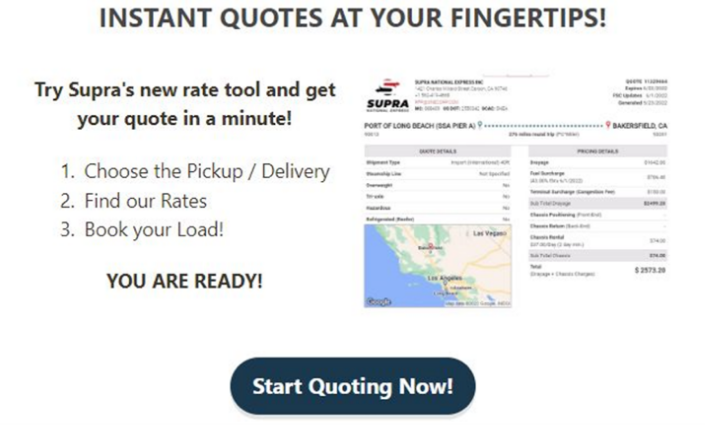

With Supra’s expertise and industry knowledge, businesses of any size can benefit from increased efficiency while saving money on costs associated with logistics management. Connect with an expert from Supra to optimize your transportation needs today. And be sure sure to check out our new online quoting tool, DrayMaster, and get your quote in under a minute.

Become A Partner Carrier

Become A Partner Carrier